Deep Hole Drilling and Bore Machining Services

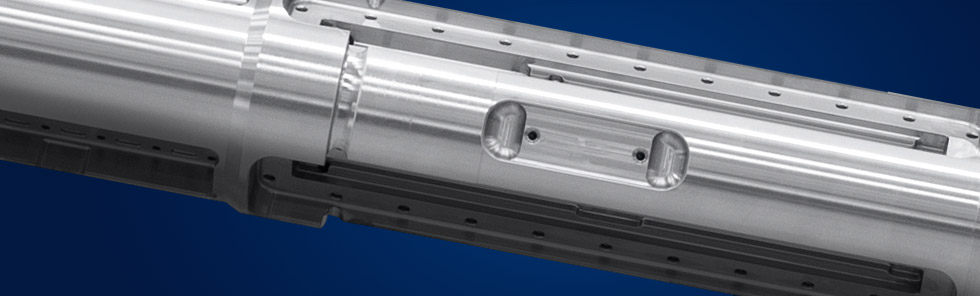

Dearborn “Leads the Way” in deep hole machining. With over half a century of innovating and perfecting the art of gun drilling, we have a wealth of experience that is un-matched within the machining industry. Innovators since our founding in 1947, everything that we do today has grown from our ability to drill deep and straight holes in long parts or unusual shapes. Whether the requirements are a uniform walled tube, an off-center blind hole, or a bore directed to hit a critical “target” zone, Dearborn has the capability, knowledge, and overwhelming drive to satisfy your needs. We produce the deepest depth/diameter ratios, the tightest positional tolerance, and closest concentricity in the industry.

As part of Hunting’s Advanced Manufacturing Group (Hunting AMG), we are dedicated to advancing the capabilities of the industry through innovative drilling solutions, which overcome the limitations offered by conventional bore machining.

As a drilling industry leader, we design and build our own gun drill machines, tooling, and related equipment, enabling us master specialized drilling techniques. Our management, engineers, and machinists work continually to improve our processes, procedures, and efficiencies. We are committed to provide our customers with advanced deep hole drilling solutions by producing tighter tolerances, with better finishes, in tougher materials.

The scope of our bore machining capabilities include: 3.0mm specialty hydraulic tubing; thin walled pressure housings; uniform wall tubes; pattern-drilling of wire or fluid passages in 30-ft long Oil & Gas formation evaluation tools; large diameter concentric bottle bores for highly balanced turbine engine shafts.

With 100+ spindles running shop wide and 140,000 square feet of manufacturing space, whether we are supplying you with highest quality pre-bored “blanks” for finishing in your own machine shop or supplying you with complex turnkey machined parts “dock-to-stock.”, our unparalleled deep hole machining capabilities help you deliver next-gen solutions…today.

Challenge us, we’re up to it!

I.D. Capabilities:

On center holes, off center holes angle holes, blind holes, bottle boring

GunDrilling:

ID Size: .055 inch up to 2 inches

Length: up to 32 feet

Trepanning:

ID Size: 2.00 inch up to 13.875 inches

Length: up to 32 feet

Re-Boring:

ID Size: ½ inch up 14 inches

Length: 6 inch up 360 inches

Honing:

ID Size: up to 12 inches

Length: up to 30 feet

Surface Finish from 8 – 32 Ra