Oil & Gas

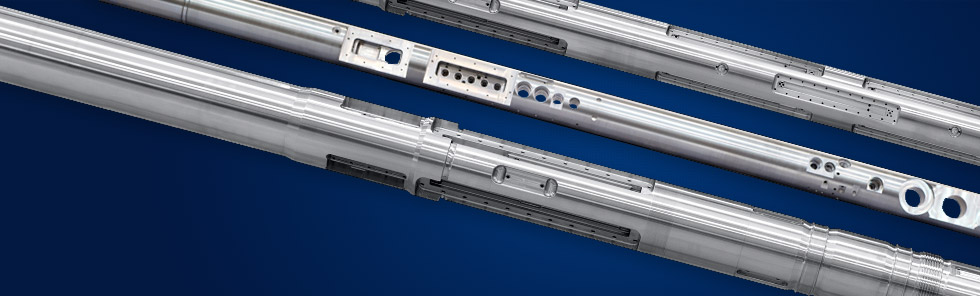

Dearborn leads the way in deep-hole drilling and precision machining of complex Oil & Gas components. For more than 60 years, Dearborn has been a key machined parts supplier to the world’s foremost energy service providers. In the quest to drill deeper, faster, and in increasingly harsh environments, today’s E&P technologies demand a level of precision which rivals that of the nuclear and aerospace industries.

Dearborn employs unique deep-hole machining capabilities, and our penchant for quality has made us a leading supplier for many oilfield service companies. Our depth of experience and broad "turn-key" machining capabilities make us the preferred supplier of high-precision machined components for today's premier oil-field service companies. Expertise in providing co-engineering for manufacturability, complete machining, wear surfaces, coatings, cladding, peening, logistics, to planning and procuring of raw material make Dearborn a full service solution.

Our specialty is drilling deep bores in high grade non-magnetic alloys such as MP35N, 718, 925, 17-4PH and titaniums. Our unique and specialized gun-drilling technology gives us the ability to produce fluid passages and wire-ways to depths and tolerances considered impossible by others in our industry. We are able to produce bores as small as Ø .055", as large as Ø 14.0” and in excess of 32-ft long.

Whether your product is an intricately machined wire-line probe, a highly engineered MWD or LWD collar, precision machined completion tools, or special uniform walled tubing for pressure housings, our unsurpassed gundrilling and deep bore machining technologies, combined with our world class machining expertise, make Dearborn the best solution for your oil & gas components.

Types of machined parts:

Directional Drilling/Geo-steering tools, Rotary steerable drive shafts & mandrels, EM Subs, Wire line tools, chassis, inserts and collars for MWD & LWD tools, Fluid Sampling/Fluid ID tools, Formation Evaluation tools (FE), Resistivity tools, Gamma Tools, Pressure Housings, Instrument collars and subs, Electronic chassis and inserts, High Pressure High Temp (HPHT) components.

Materials we machine:

HDI has experience machining virtually all Non-mag, corrosion resistant and HPHT stainless alloys available today, including duplex chrome, 925, 718, MP35N, Hastelloy, Toughmet, Ti Beta-C, 6al4V Titanium, 17-4PH

Our Services:

• Drilling high quality pre-bored blanks for final machining by our customer

• CNC machining of complex finished parts

• Materials management

• Integrated supply chain solutions

• BOM management

• Electro mechanical assemblies

• Welding

• UT, magperm, FDP and UT inspection

• CMM inspection services

• Thread Root rolling

• Bore burnishing for cold work

• Bore burnishing for critical seal surfaces in long instrument collars

• Shot-peening

• Laser welding

• Hard-facing & wear cladding

Our Quality:

Dearborn is ISO9001-2000, API and DS-1 compliant.