Dump Bailer

Applications

- Dump cement or sand onto a bridge plug

Features

- Gravity activated system

- Strengthened upper window sections

- Ballistic or mechanical actuation

Benefits

- Cost effective and low maintenance

- Explosives not always necessary

- Full toolstrings can be rigged up in one piece reducing operating time

Dump bailers are primarily used for dumping cement (sand is also an option) on pre-existing bridge plugs. Placing cement on top of a bridge plug allows for a larger pressure differential to be placed across it. The cement can also be used to plug off unwanted water producing perforations.

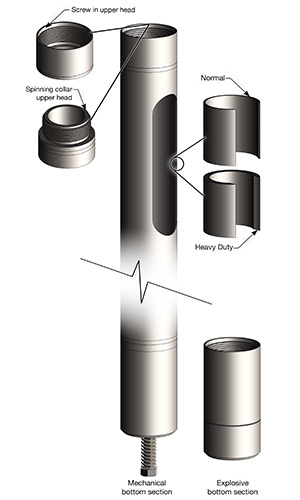

Titan dump bailers are gravity activated systems. This simple, yet effective, design is the most common type of system used in the industry. Cement is simply poured into the dump bailer. A glass rupture disc at the bottom of the chambers holds the cement inside the tool. Once above the bridge plug, the glass disc is broken and the cement, under the influence of gravity, falls freely onto the plug. Options are also available for heavy duty top section windows. These provide extra support for long dump bailer toolstrings at the filler window, which is the weakest part of the string.

Two types of activation systems are available from Titan. A small blasting cap can be placed on top of the glass rupture disc and actuated when required. The other method uses a mechanical striker pin. When the dump bailer hits a bridge plug with force, the pin strikes the glass disc rupturing it.