IFJM11

Applications

· Production profiling

· Injection profiling

· Logging in sand screens /slotted liners

· Particularly good for use In high velocity

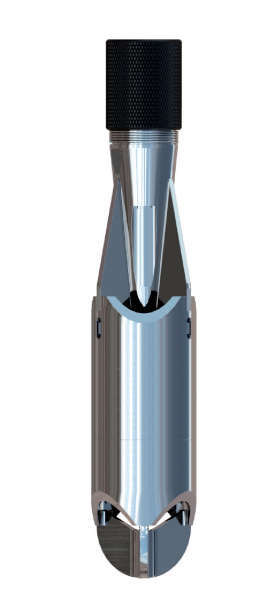

The Jeweled Bearing Flowmeter (mechanical section) employs jewels for the support of the spinner pivot to reduce threshold displacement and improve sensitivity. The tool is very rugged as the housing provides the spinner with good protection. The flowmeter is applicable to all deviations, from vertical to horizontal.

The HTF02 is connected to measure the downhole flow rate. The mechanical section is composed of upper sub, outer cage, spinner and central spindle. Both ends of the central spindle are supported by a jeweled bearing respectively. Moving fluids flowing through the spinner may rotate the spinner, which then rotates the magnetic steel on the central spindle to trigger Hall device assembly in the HTF02 to generate 10 pulsed signals per revolution. The signals are processed in circuits first and then transmitted to the surface system.