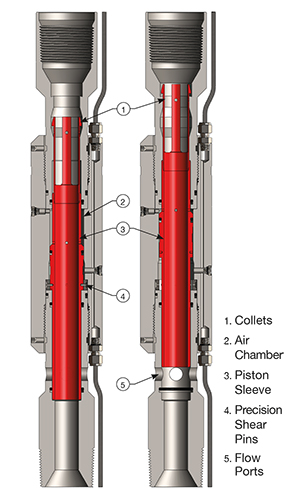

Annular Pressure Operated Production Vent

Applications

- Highly deviated or horizontal permamanent completions

- Underbalanced perforating

- Drillstem Testing (DST)

Features

- Annular pressure bar operated

- Compatible with Dual Top Annulus Differential Pressure Firing Head

- Ideal for perforating underbalanced in wells with existing perforations

- Collets ensure that once the valve opens, it cannot close

Benefits

- Required underbalance will ensure proper perforation cleanup potentially improving productivity or injectivity

- Ideal for completions where wireline or slickline tools cannot be used because of high deviation

Creating underbalanced perforating scenarios using a permanent completion string in a well that already possess open perforations can be challenging as only tubing pressure and annular pressure above the packer can be manipulated to fire the guns and open the well for surging. Annular Pressure Operated Production Vent allows this to be possible.

The Annular Pressure Operated Production Vent prevents fluid entry into the tubing while running in hole. The desired underbalance can be achieved by topping up fluid from surface or using the Fill/Stop Fill Valve. This will vary from job to job depending on well conditions. The production vent can also be configured to set packers and liner hangers.

The production vent is run with the Packer Bypass Assembly and Dual Top Annulus Differential Pressure Firing Head. By manipulating the annular pressure above the packer, the gun system can be initiated followed by opening the flow ports allowing fluid to surge into the tubing. This setup is ideal for highly deviated or horizontal completions where drop bars cannot be deployed and wireline or slickline intervention is not possible.

A drop bar actuated version of the production vent is also available.