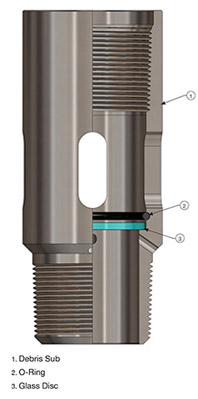

Ported Debris Barrier Sub

Applications

- TCP perforating operations

- Underbalanced perforating

Features

- Heat treated glass used to make strong, durable discs

- Large elongated ports incorporated into the body

Benefits

- Debris can be circulated out prior to dropping a ball or bar

- Permits displacement of tubing to lighter fluid or nitrogen

- Ports larger than cross section of tubing allow unrestricted flow

- Allows tubing to be filled while running in hole

The Ported Debris Barrier Sub is an inexpensive device that provides flow ports and a barrier to prevent debris from falling onto mechanical or pressure activated firing heads.

The ports are elongated to allow large debris to pass through unhindered while retaining high mechanical integrity within the sub. It also allows unrestricted fluid flow through the tubing by having a cross sectional area greater than the tubing itself. This provides an ideal setup during well testing.

The heat treated, high strength glass disc is sealed in place to allow clean fluid to remain above the firing head.