Ball Drop Hydraulic Actuated Firing Head

Applications

- Coiled tubing or TCP perforating

- Overbalance and underbalance perforating

- Highly deviated and horizontal wells

- Wells with existing perforations

- Well abandonment

Features

- Can circulate before and after perforating

- Designed to API RP-67 (Oilfield Explosives Safety) guidelines

Benefits

- Ideal for single trip operations requiring pre- and post-perforating clean up

- Enhanced safety as firing head can only be activated by properly seated ball

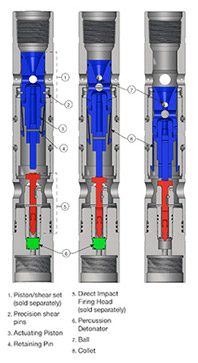

The Ball Drop Hydraulic Actuated Firing Head is ideal for coiled tubing perforating or pipe recovery services. Having the ability to circulate before and after perforating offers a range of extra single run operations, for example, cement squeeze jobs. The well can be circulated clean prior to perforating followed by the cement squeeze post perforating, all in a single run.

A steel ball is dropped or pumped down the tubing and seats into an actuating piston, which is held in place by precision shear pins, the number of pins determined by the well conditions and desired safety factor. A differential pressure is then created across this piston which shears the precision shear pins. The actuating piston is then driven into a Direct Impact Drop Bar Firing Head which in turn detonates the gun assembly. The firing head can also be configured to utilize the Drop Bar Hydrostatic Firing Head system.

After impacting the firing pin, the actuating piston continues to be driven down by differential pressure shearing the retaining pin. A continued downward movement allows the collet to lock into the housing. This prevents the flow ports from sealing should reverse flow occur.